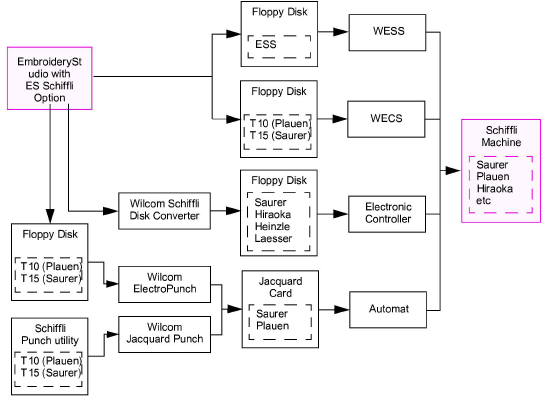

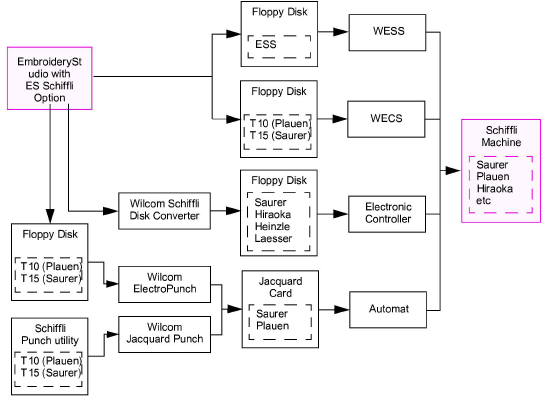

Once a design has been saved to the appropriate format, you can output it for stitching in a variety of ways as shown in the diagram below.

Note: The Wilcom Jacquard Punch and Wilcom ElectroPunch devices are no longer supported by Wilcom.

WESS (Wilcom Electronic Servo System) replaces the Schiffli Automat and controls the frame movements directly by servo motors. It requires Wilcom ESS, Hiraoka DAT, Saurer SAS, T10 or T15 files on floppy disk as input and its method of operation is similar to WECS. See the Wilcom WESS Operator Manual for details.

Note: ESS is the primary machine file format for Wilcom-developed Schiffli servo control systems. When the ESS file is read directly by WESS, high resolution and stitch accuracy is possible. If your machine uses a WESS controller, you need only output a single ESS file.

WECS (Wilcom ElectroCard System) eliminates the need for Jacquard cards. WECS reads Wilcom machine files T10 and T15 and runs the Schiffli Automat directly. You therefore only need to save the design as a machine file to floppy disk. See the WECS Operator Manual for details.

Wilcom ElectroPunch takes T10 or T15 files as input. You need to copy these files to a floppy disk or directly via File > Save As to floppy disk. See the Wilcom ElectroCard/ElectroPunch User Manual for details.

The Schiffli Punch utility for Windows sends a T10 or T15 tape file from your PC to a Wilcom Jacquard Punch, the predecessor of the ElectroPunch. See also Punching machine files to Wilcom Jacquard Punch (Supplement).