On a mechanical Schiffli machine everything is activated by the rotation of the main shaft. Borer depth moves forward or back by one notch each rotation. So if it needs to move five positions, it requires five full turns of the main shaft.

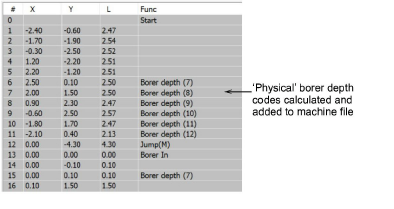

Remember that what you see in the Stitch List is the ‘logical’ borer depth and not the ‘physical’ Borer Plus and Borer Minus functions interpreted on the machine. These are inserted by ES Schiffli during final encoding.

Let’s say the default Borer Depth is 6. The digitizer wants to make a very small hole and change Borer Depth to 1. However, with mechanical machines, the borer can be moved only by one unit per revolution/stitch. This means it will take 5 revolutions for the machine to move borer depth from 6 to 1. ES Schiffli therefore starts adding -1 Borer Depth commands 5 stitches before the Borer Depth 1 point.

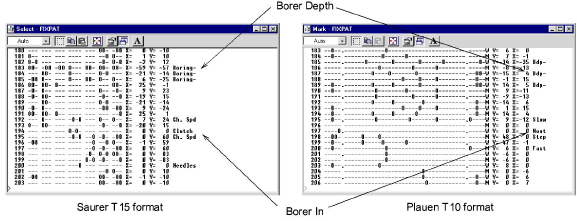

These incremental borer depth adjustments are automatically calculated and added to the machine file. If there are no actual stitches before the insertion point, they are automatically added as empty stitches. When exported as a Saurer SLC (SAS) file, this is how it gets encoded...

Since the digitizer does not know the status of the Borer Depth on the machine, ES Schiffli returns to the default Borer Depth value at the end of any borer hole sequence. Since no more stitches are left at this point, ES Schiffli inserts enough empty stitches to hold the necessary Borer Depth commands.

Note: For electronic machines, these steps are not necessary because boring devices are controlled by servo motors independent of the main motor.

Logical functions in EmbroideryStudio are translated to the following physical functions in the Plauen (T10) and Saurer (T15) machine files.

|

Logical function |

Physical functions Plauen |

Physical functions Saurer |

|

Borer In |

|

|

|

Borer Out |

|

|

If you are concerned about the function sequence, you can check the software output in the Plauen or Saurer files using the FIXPAT utility.